Sweater Manufacturing Process A to Z – Flow Chart

What is Sweater?

A piece of

clothing made from wool, cotton, synthetic fibers or combinations of these is

called sweater. Sweaters are made for adults and children (from new born baby

to adult’s sizes).

Kinds of Sweater:

·

Long/Short Sleeve Pullover

·

Long/Short Sleeve Cardigan

·

V-neck Sweater

·

Crewneck Sweater

·

Slipover/Sleeveless ( Vest )/Tank top Sweater

·

Hoodie

·

Mockneck

·

Turtleneck

· 1/2 Zip and Full Zip Sweater Etc.

Sweater

Manufacturing Process:

|

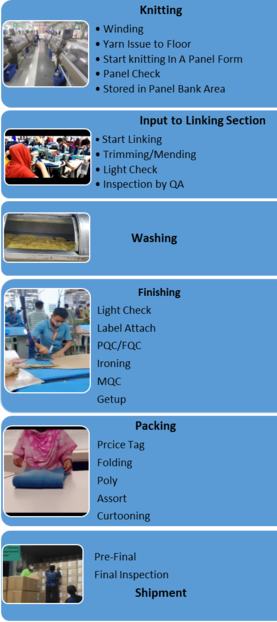

| Sweater Manufacturing Process A to Z – Flow Chart |

1. Yarn Sourcing: Yarns are the main raw

materials to make a sweater. Merchant dept. start sourcing of yarn after confirm an order based on customer requirement.

2. Winding: Normally yarn in-house in factory store from supplier in hanks / spool form. So need to winded into cones by using Winding machine. After winding, those cones will store in yarn distribution section to distribute for knitting production by keeping proper record.

3. Yarn Issue to Floor: Yarn distributor will collect it as per plan and distribute to the knitting operator. Yarn distributor will maintain proper document of yarn receiving and issuing data.

4. Start knitting In A Panel Form: Knitting operator knit panel by knitting machine and make bundle with 10 to 12 pcs for next process.

5. Panel Check: Check knitted panel 100% to find different types of faulty panel to rectify or replace those. Because faulty panel will kill valuable productive time in next section.

6. Stored in Panel Bank Area: A specific area to keep the color wise panel separately. Panel Distributor of Knitting have a vital role here maintaining panel issuing data by counting. Record customer, color and size wise quantity as per PO sheet.

7. Input to Linking Section: Linking distributor is responsible collecting panels from panel bank area and give input to linking line. One helpers also allocate with him to provide required knitting accessories to the linking operator. Recording data is a big role of linking distributor also to complete the order po wise.

8. Start Linking: All the knitting panels are attach together as per process layout by linking machine to give a complete look of sweater. Follow quality instructions as per approved sample to maintain customer requirements. In traditional sweater factories- linking operators complete all the process individually. But currently in some factories introduce process wise separate operators as per layout and get significant result in productivity.

9. Trimming/Mending: Trim all uncut/loose yarns & put tack on joint area as per quality requirements. Pull neck/ piping area to find in case of drop needle, open/broken seam & mark it by neck pulling operator. Mending operator will rectify those faulty areas.

10.

Light Check: Check all seam areas of a complete sweater - side seam, shoulder & full back/front panel to find linking & knitting defects by light check machine.

11.

Quality Check: Check all the areas to ensure overall quality as per approved sample.

12.

Inspection by QA: Inline QA randomly check here to take necessary steps immediately in case of any quality failure.

13.

Send to Wash: Another linking distributor will send quality pass garments to wash by physical counting and keep record.

14.

Washing: This is very important to meet shrinkage label of sweater by washing. If there any wrong recipe used while washing, then it may not meet standard level of measurement or sweater's hand feel. Wash sweater following customer recommendation for cotton and acrylic based sweater.

15.

Special Attachment: There have a separate areas for special attachment. If there any special attachment like zipper, back moon, elbow, neck tape etc then complete those process in separate areas.

16.

Fin Input: Fin distributor will give input to line as per plan & keep proper record po wise.

17.

Light Check: To find defects, do light checking again. Because after washing, there are possibilities in Broken stitch, Color bleeding, uneven dyeing etc.

18.

Label Attach: Sewing operators attach necessary labels ( main label, care label, hanger loop etc).

19.

Quality Check - PQC/FQC: Check inside & topside to find defects. Trim all uncut thread & loose yarn.

20. Ironing: Board cutter keep ready iron board size wise by following customer provided measurement sheet. Iron operators doing steam iron using iron board & steam iron machine.

21.

Measurement Check: Measurement QC check those iron complete pieces 100% to ensure customer requirements.

22.

Get-Up Check: Getup operator check all the attached accessories are as per approve sample & overall outlook.

23.

Inspection by QA: Inline QA will check randomly to ensure acceptable quality level.

24.

Packing: price tagging, folding, poly, assorting & cartooning are doing here as per instruction of PO sheet to ready the goods for inspection.

25.

Internal Audit: Internal QA/ GPQ will conduct internal audit/ pre-final inspection to check ready goods & packing method including accessories are as per requirement. Then offer customer nominated Inspector for final inspection.

26.

Final Inspection: Buyer assign quality team conduct final inspection according to the customer instructions.

27.

Shipment: Finally after getting inspection pass, Then goods load to vehicle and send to port for shipment.🚒

This is all about manufacturing sweater product. If you think to add more points here, please help to improve this post for others reader.

Read also: Application of Industrial Engineering in Sweater Industry

Can you specify the machines used and number of men used at each step of the process described above. Then we can discuss about process machine effort IE and process human effort IE.

ReplyDeleteI included the link to your blog in my post.

Machine Work Study in Garment Manufacturing Factories

Machine Work Study in Garment Manufacturing Factories