Different types of major defects of sweater factories

What is Defect?

Failure of customer requirements to make a product is called defect. In other words, a lack of something that results in incompleteness of quality standard of a product is called defect.

No one like to produce defective garments but it is common problems for any manufacturing unit. So before sending goods to next section and before offering goods for final inspection, find & rectify all defects.

Every section of a production unit have check point where QC check from yarn stage to pack complete garments to ensure right quality of products. Because it's the fact of company reputation & customer satisfaction.

Classification of defects:

It is very important to understand different types of defect and source of the defects. We will discuss all about defects here category wise.

Defects are mainly in 3 categories those are,

1. Critical: Safety issue for a user/consumer & violate mandatory regulations of buyers is treated as Critical defects. It directly hit on company reputations & getting next order from buyers.

For Example:

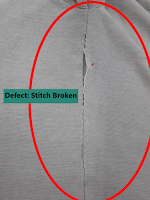

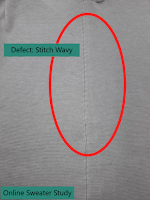

2. Major: A defect that is reducing usability/sale ability of a product is treated as Major defects. It causes of bad reputation for a factory & less sales.

3. Minor: A defect that usually happens for the poor workmanship is treated as Minor defects. It's not hampering in sales but it causes of shorten life cycle of a product.

|

| Linking Alter |

- Slabs

- Naps

- Yarn thick & thin

- Spot on yarn

- Uneven yarn dye

- Barriness

- Knot

- Foreign Yarn

- Needle drop

- Puckering

- Yarn Twist

- Cut damage

- Wrong placement of hole mark

- Shading due to lot mistake

26. Over Stitch

No comments