8 wastage factor in garments industry.

Waste:

All unused things/resources in a production unit can be defined as waste. It happen in every section of production unit like knitting/cutting, assembly, finishing & packing.

For example: Due to machine setting wrong or instruction wrong, a countable number of quantities has produce by the team member. But that pieces can't ship because of quality issues and every pieces again need to rectify. So all the rectify time of those team members are definitely will be waste. On the other hand, Knit / Cut 3% extra of order quantity, but customer will not take any extra pieces than the order qty so all the extra pieces producing time will be waste. And materials also co-related with this wastage factor. Some customer also take extra pieces from1 to 5% as per agreement.

So simply we can express waste like

"All the non value added activities for which the customer/buyer would not be willing to pay is called waste."

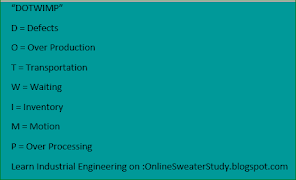

There are 7 major wastage factor in garments manufacturing unit. To memorize it in a easiest way, just keep in mind " DOTWIMP" as a word.

|

| 7 Major Wastage in garments Industry |

Defects: Producing defects directly hit on wasting money and effort. No one are coming to work for producing defective garments. Company also not recruited anyone for this. As everyone in the factory are aware that no defective garment can be shipped. So however after producing defects, factory has to rectify those defective garments before ready to offer for inspection and it just waste valuable productive time and money. Some familiar defects are : Panel shade, wrong knit/cutting, uneven stitch, open stitch, stitch broken, cut damage etc. Some reason for defects are given below,

- Machine not set properly

- Incorrect method or wrong instruction

- Faulty panel

- Lake of quality awareness

Over Production: Every people are working on floor for getting right production within the time period. Then why over production treated as waste? Yes sometimes over production can be waste. Because in a month make 50000 pcs excess than the plan pcs but on following next week people are sitting idle due to panel not available (Yarn / Fabric/Accessories for next order not inhouse early as requested to inhouse for continuous feeding). Plan not work here and it create waste here. It may create excessive WIP / Bottleneck on next process.

On the other hand Early production also considered as over production. This means customer not demand shipment now but factory producing in advance. It creates excess inventory.

Transportation: Panel/ Garments always moving one section to another section, operator to another operator over the trolley, bins etc. All kinds of transportation are non value added services but has to do although customer not paying for this.

Waiting: People wait for the sufficient input from previous sections and previous operations also. Transportation makes them waiting for work in case of delays or imbalance line. It interrupts normal flow of production. Its like production supervisor wait for any kind of approval or instructions, operator wait for the feeding creates waste.

Inventory: It is a must required process of a manufacturing unit. Inventory normally represents all the necessary and idle resources/materials of a factory. So what are the resources/materials are in stock more than the demand of the following process treated as excess inventory. Inhouse materials more early also waste of inventory.

Motion: In every workstation, people are using some excess/unnecessary motion while working. Lake of proper training, not following standard method and poor line layout creates this. Read how to eliminate excess motion by Method Study.

Processing: All the non value added process of manufacturing unit treated as over processing waste those are not required from the customer. Factory internally perform that process to give good outlook of product additionally for which customer not going to pay.

Already we have discussed about 7 major wastage factor in a manufacturing unit in day to day activities. But Not-Utilizing Talent also one kind of waste in lean manufacturing process. Insufficient use talent, knowledge and abilities of people has massive impact for any company. The motivational impact of people directly hit on productivity. Some common reason of talent waste are-

- Assign people in wrong task

- Not provide opportunities to the well capable inside people

- Lack of training

- Lack of teamwork

- Poor management.

Ubiquity of Industrial Engineering Principle.

ReplyDeleteIndustrial Engineering is applicable to all branches of engineering.