What is Balancing loss & How To Calculate It?

The work content / capacity distribute equally among the all team members of a line is called balancing. Production always smooth from a well balanced line. Responsible IE & production team always should follow to balance the line equally.

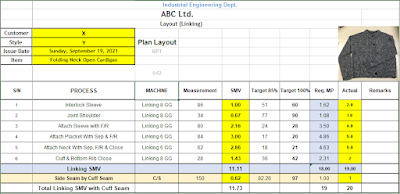

In a Layout, some operations required fractions number of machines & manpower. But manpower/machine cannot use as like fraction figure. That means if required 1.2 MP or machine, use round to 1 instead of 1.2 and if required 1.5 or more then use round 2 there.

Balancing loss= (Total allocated MP-Total required MP)÷ Total required MP

|

| Sample Layout of a Sweater Product |

So Balancing Loss = (20-19)÷19

=1÷19

=5.26%

Total Variation of the allocated & required team members is known as balancing loss. The effectiveness of line balancing can measured by balancing loss. In effect kill the valuable productive time through unequal allocation of workload.

Recovering Balancing Loss:

By sharing workload from high work content to low work content. we can rebalance the line. By observing capacity graph we can allocate some work to the operations with higher capacity than required for the line target. Read this also to know about Line Balancing.

No comments