Difference Between Defect and Defective Product with Example. How to Measured those?

Defect:

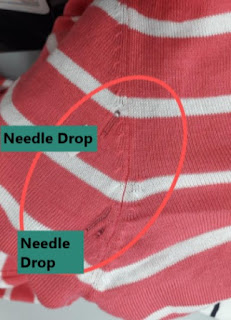

When a product not meeting specific requirement of the customer is called defect. In other words, A defect is a parameter which decide a garments is passable or not. Lack of standard requirement of a product or services is treated as defect. Like Sleeve / back-front part up-down, Broken Stitch, Skip Stitch etc.

Defective:

Defects occurred in any pieces is called defective pieces. That means defective pieces/ any kinds of product are those item in which found at least one defect & quality checker keeps them separate from good pieces for further process. In a defective pieces, there may contain one or more defects. When defect and defective garments are very less means within the tolerance among the PO quantity is considered as good quality. But if defects / defective garments are high is considered as the bad quality. Achieving right quality is not only QA department responsibilities. Quality is everyone's responsibility.

|

| Defective Garments |

Quality checkers are recorded all those data regarding defect & defective pieces in a company provided sheet on hourly basis. Quality & production team will follow these report to solve the issues. For better follow-up, there are two measuring types are commonly used in factories.

- DHU - Defect per Hundred Units

- Defective %

Total number of defects found in 100 pieces checked. Formula to measure DHU is,

DHU = (Total number of defects found*100)/no of pieces checked

For Example, A quality checker has checked 80 pcs sweater / garments on first hour. He /she has found 10 pcs defects from 7 defective garments.

So, DHU = (10*100)/80

=12.5

Learn more details about How to Measure DHU in a Manufacturing Unit?

Calculating Defective %:

Total number of defective garments found in 100 pieces checked. For Example, Considering first data,

Defective % = (Total number of defective garments found*100)/no of pieces checked

= (7*100)/80

= 8.75% On First Hour

If a checker found 45 defective garments among 640 pcs inspected quantity then defective percent will be,

Defective % = (Total number of defective garments found in a day*100)/no of pieces checked

= ( 45*100)/640

= 7%

There is no alternative achieving quality. Because bad quality waste valuable productive time & wasting money. And right quality is the fact of company reputation and customer satisfaction.

Read More: Different types of major defects of sweater factories

No comments