Difference between Productivity & Efficiency

Difference between Productivity & Efficiency:

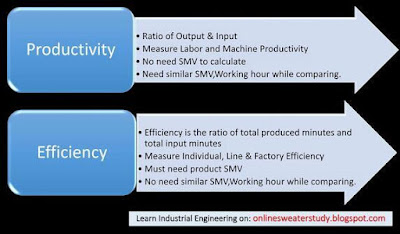

Productivity:

The ratio between

Output & input is called Productivity. Productivity is a very familiar word

in any production based organization. Cost are going high day by day. To

minimize manufacturing cost and make a company more profitable, increasing

productivity is the best way. Productivity can be measured of Labor Productivity

and Machine Productivity of a production line and whole factory as well.

Productivity expressed in pieces. For labor productivity it will – Number of pieces

produced per labor and for machine productivity it will – Number of pieces

produced per machine. Learn more details about How to increase productivity.

Equation of measuring Productivity = Output ÷

Input

Efficiency:

Efficiency is the

ratio of total produced minutes and total input/working minutes. Efficiency

always expressed in percent. Efficiency is measured for Individual Operators,

Production Line & Whole Factory Efficiency.

Equation of calculating Efficiency is as follows,

Efficiency = (Total Output Minutes ÷ Total Input Minutes)*100

Or, Efficiency = (Total Output Hours (SAH) ÷ Total

Input Hours)*100

|

| Difference Between Productivity And Efficiency |

For Example no 1.

A line of 20 operators produced 800 pcs yesterday in 10 hours shift where product SMV is 11.25 , now calculate productivity & efficiency of that line to see the difference in results.

Labor Productivity = 800÷20 (Here Output is Produced quantity

800 pcs & input is 20 operator)

= 40

Pcs

Calculate Efficiency,

Total Output Hours (SAH) = (Output*SMV)÷60

=

(800*11.25)÷60

=9000÷60

=150

Hour

And Input Hour = Manpower * Working Hour

=20*10

=200

Hour

So Efficiency = (Total Output Hours (SAH) ÷ Total

Input Hours)*100

= (150÷200)*100

=75%

That is the main fact of Productivity in Pieces and Efficiency in

percent. Both are important and use to understand individual, a line and

factory performance.

To compare productivity with another line, it is very important

fact is product category and SMV. With different SMV and manpower, comparing

productivity will not figure out right things. Need same style and SMV while

comparing productivity with others team and factory as well.

For better understand, here is the Example no 2,

A line of 18 operators produced 400 pcs yesterday in 10

hours shift where product SMV is 20.25 , now calculate productivity &

efficiency of that line to see the difference in results.

Here, Labor Productivity = 400÷18

=22.22

Pcs

And Efficiency = (400*20.25*100)/ (18*10*60)

= 75%

Now if we compare both example, see different productivity 40 pieces in example no 1 and 22.22 pieces

in example no 2 where efficiency is same 75% in both case. I think now

clear about the differences between productivity and efficiency.

Read Also: Job Responsibilities of an Industrial Engineer ( IE ).

No comments